When launching a custom injection molding project, prototyping is a crucial step that is often overlooked. This stage is not just about visualizing an idea, but it’s about bringing it to life, refining it, and ensuring it is viable for mass production. Prototyping offers a tangible way to test and improve product designs, ultimately leading to better products and a more efficient manufacturing process.

Why Prototyping is Important:

1. Risk Reduction: Prototyping significantly reduces the risks associated with launching new products. By creating a physical model, you can identify and rectify design flaws early, preventing costly mistakes in the mass production phase.

2. Cost-Effectiveness: Early detection of design flaws means less money spent on revisions during the production stage. Prototypes allow for cost-effective troubleshooting.

3. Time Efficiency: Prototyping accelerates the time-to-market. By identifying and solving issues early, the overall development time is shortened.

4. Stakeholder and Customer Engagement: Prototypes offer a tangible product for stakeholders to interact with, providing a clearer understanding and often leading to more constructive feedback and support. This also allows for up-front selling opportunities before the capital is invented in the production mold.

5. Customization and Optimization: In custom injection molding, the requirements are often unique. Prototyping helps in customizing and optimizing the design specific to the project needs.

Types of Prototyping in Injection Molding

1. Soft Tooling

Soft tooling, also known as prototype tooling, involves creating molds from softer, less durable materials like weak aluminum alloys. This method is faster and less expensive than traditional steel molds, making it ideal for low-volume production and initial testing phases.

Advantages:

– Speed: Quicker to manufacture than steel molds.

– Cost: Less expensive, suitable for limited budgets.

– Flexibility: Easier to modify or tweak during the development phase.

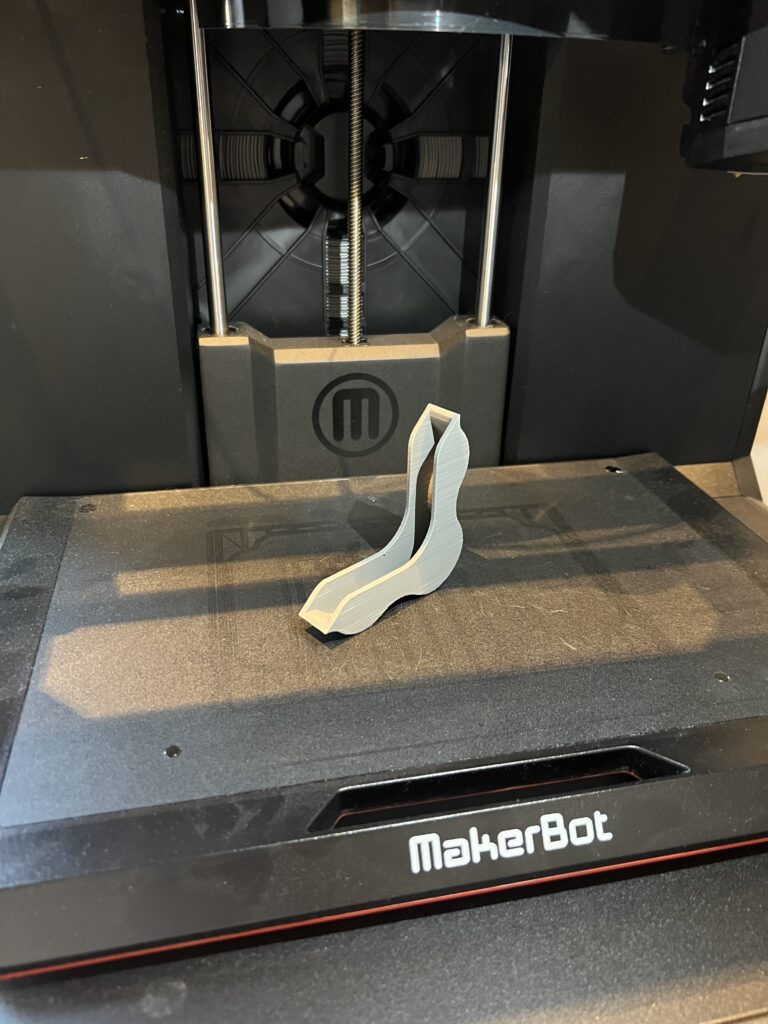

2. FDM (Fused Deposition Modeling) 3D Printing

FDM 3D Printing involves the additive process of laying down material in layers to create a part. This method is widely used for creating prototypes due to its accessibility and versatility.

Advantages:

– Complexity: Allows for the creation of complex geometries that might be difficult or impossible with traditional manufacturing.

– Material Variety: A wide range of materials can be used, enabling testing with different physical properties.

– Speed and Cost: Rapid and cost-effective for producing small numbers of parts.

3. SLA (Stereolithography)

SLA is a form of 3D printing that uses a laser to cure liquid resin into hardened plastic in a layer-by-layer fashion. It is known for its high accuracy and smooth surface finish.

Advantages:

– Detail and Accuracy: Produces parts with high detail and tight tolerances.

– Finish: Parts have a smooth surface, ideal for visual prototypes.

– Material Options: Provides a range of resin options that can simulate various plastic materials.

4. SLS (Selective Laser Sintering)

Selective Laser Sintering (SLS) is a 3D printing technique that uses a laser to sinter powdered material, typically nylon or polyamide, into a solid structure based on a 3D model.

Advantages:

– Strength and Durability: SLS parts are more durable and suitable for functional testing.

– No Support Structure: The powder bed acts as a support, allowing complex geometries without additional support structures.

– Material Efficiency: Unused powder can be recycled for future prints.

Conclusion

In conclusion, prototyping can be a crucial part of the custom injection molding process. It not only ensures a higher success rate for the final product but also streamlines the development process, saving time and resources. With various prototyping methods like soft tooling, FDM 3D Printing, and SLA available, businesses can choose the most suitable approach based on their specific project requirements, budget, and timeline. Embracing prototyping is a step towards innovation, efficiency, and market success in the competitive world of product manufacturing.

—

Montrose offers all of these prototyping services and would be happy to assist you in the launch of your next project. Click here to speak with one of our technical sales representatives.