By Brendan Wilson

In the ever-evolving landscape of manufacturing, the injection molding industry stands at the forefront of innovation. As technology advances and consumer demands shift, staying abreast of the latest trends is crucial for businesses aiming to thrive in this competitive sector. In this blog post, we explore key trends shaping the injection molding industry and how these developments are influencing the way we design, produce, and deliver plastic parts.

-

**Industry 4.0 Integration: The Rise of Smart Manufacturing**

The injection molding industry is undergoing a profound transformation with the integration of Industry 4.0 technologies. Smart manufacturing processes, driven by the Internet of Things (IoT), artificial intelligence, and data analytics, are enhancing efficiency and reducing downtime. Real-time monitoring of machines, predictive maintenance, and data-driven decision-making are becoming integral components of modern injection molding facilities.

For example, Montrose monitors critical metrics such as scrap, yield, and downtime by wirelessly tying each injection press to the IQMS ERP system. This enables anyone in the company to know exactly how each machine is performing in real-time.

-

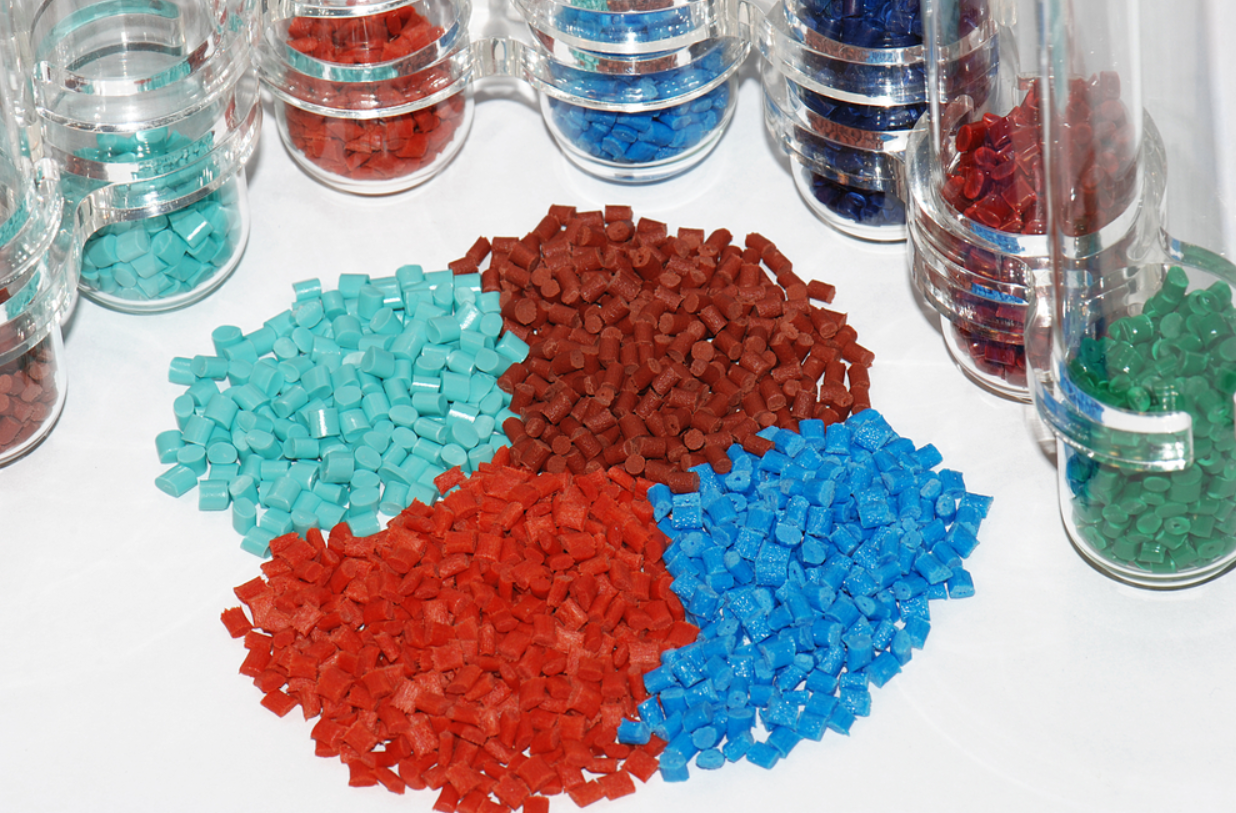

**Advanced Materials and Composites: Pushing Boundaries**

Material science is a driving force in injection molding innovation. Manufacturers are increasingly exploring and adopting advanced materials and composites that offer enhanced performance, durability, and sustainability. Biodegradable polymers, high-performance resins, and recycled materials are gaining traction as the industry places a greater emphasis on environmental responsibility.

-

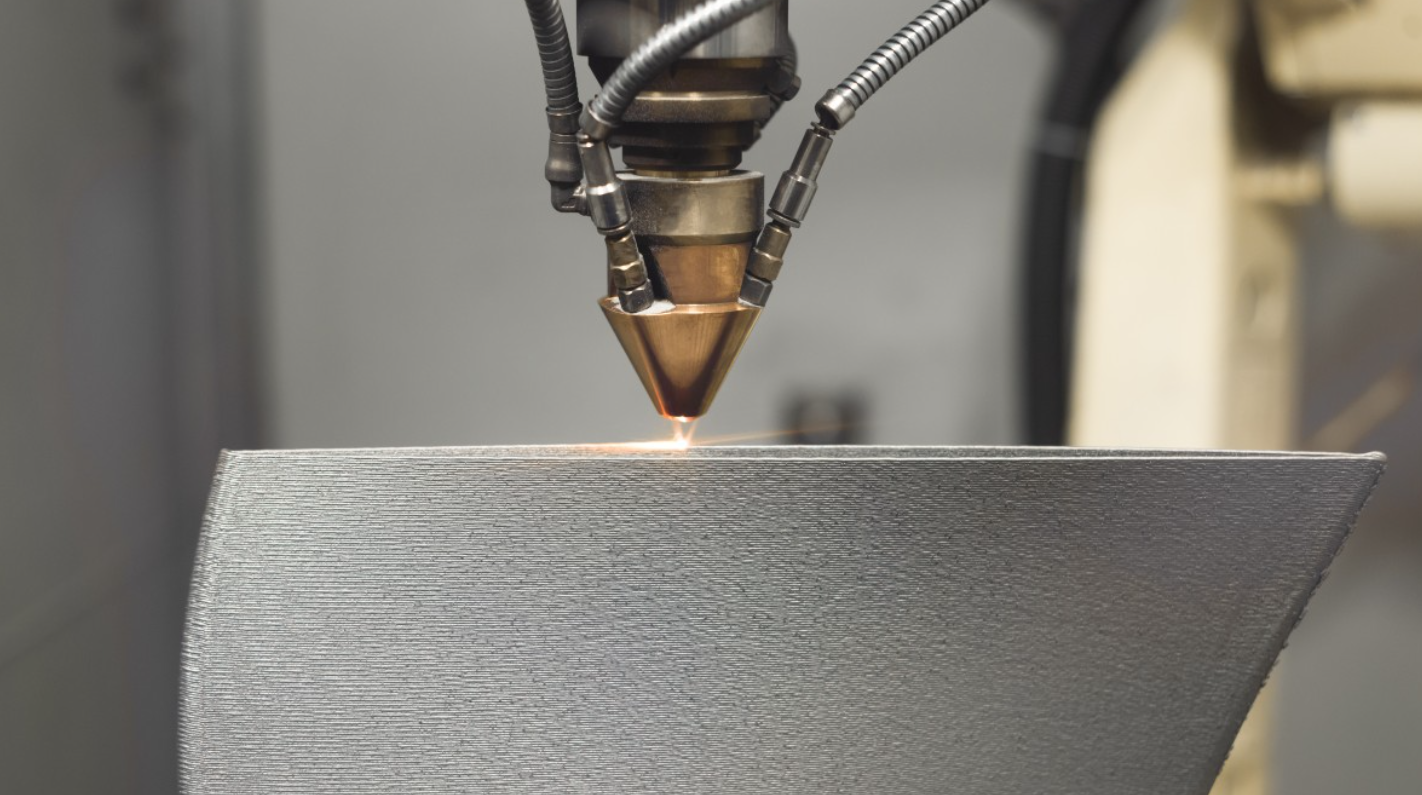

**Additive Manufacturing Synergy: Molding and 3D Printing Unite**

The synergy between injection molding and additive manufacturing is opening new avenues for design flexibility and rapid prototyping. Hybrid manufacturing processes that combine the strengths of both technologies enable the production of complex, customizable parts with reduced lead times. This trend is particularly valuable for industries demanding intricate designs and low-volume production.

But 3D printing is not limited to plastic resin. Increasingly, tool and die inserts are being printed in order to cut down on programming and machining time.

Montrose leverages its 3D printing capabilities to help customers with both prototyping and low-volume component production.

-

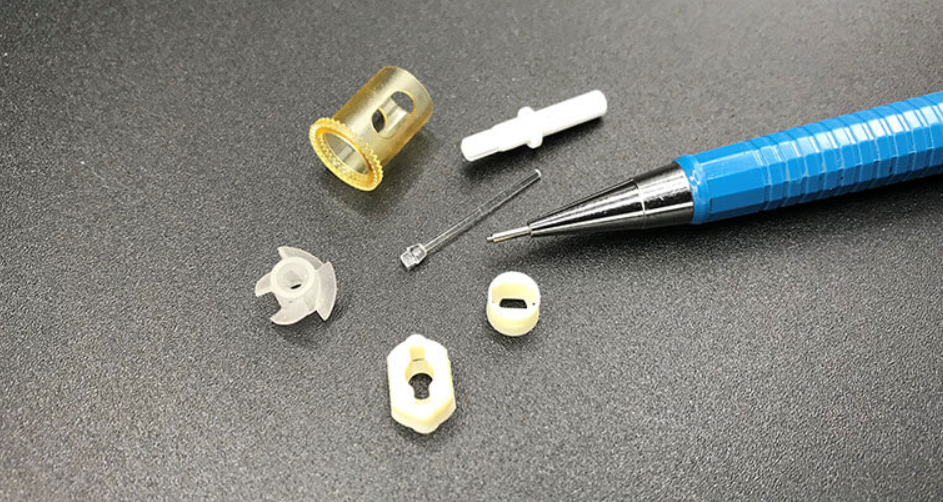

**Micro-Injection Molding: Shrinking Dimensions, Expanding Possibilities**

As electronic devices and medical components continue to miniaturize, the demand for micro-injection molding is on the rise. This specialized process allows for the production of tiny, intricate parts with high precision. From medical implants to electronic connectors, micro-injection molding is pushing the boundaries of what is possible on a miniature scale.

-

**Sustainability at the Forefront: Green Injection Molding**

Environmental consciousness is a driving force behind current injection molding trends. Companies are adopting sustainable practices by utilizing recycled materials, reducing waste, and implementing energy-efficient processes. Green injection molding is not just a trend; it’s a commitment to minimizing the industry’s ecological footprint and meeting the growing demand for eco-friendly products.

Montrose is embracing this trend, offering its customers a wide range of recycled plastics and bio-resins. Click here for more information.

-

**Customization and Personalization: Meeting Unique Demands**

Consumer preferences are increasingly leaning toward personalized and customized products. Injection molding is responding to this demand by offering more flexible manufacturing processes. From color variations to unique textures, customization is becoming more accessible, allowing manufacturers to cater to niche markets and individualized consumer needs.

In conclusion, the injection molding industry is undergoing a transformative period, driven by technological advancements, material innovations, and a growing commitment to sustainability. Companies like Montrose that embrace these trends and adapt their processes accordingly will not only stay competitive but also lead the way in shaping the future of injection molding. As we navigate this era of change, the injection molding industry is poised to deliver more efficient, sustainable, and customized solutions than ever before.