The medical industry, always at the forefront of adopting innovative technologies, has increasingly turned to injection molding for the production of a wide range of medical components. This versatile manufacturing process not only meets the high standards of precision and cleanliness required in medical applications but also offers numerous advantages when it comes to the design and production of medical devices and components. In this blog, we will delve into the role of injection molding in the medical industry, the advantages of using a contract injection molder, the benefits of plastics in medical applications, and the adherence to critical ISO and FDA standards.

The Role of Injection Molding in the Medical Industry

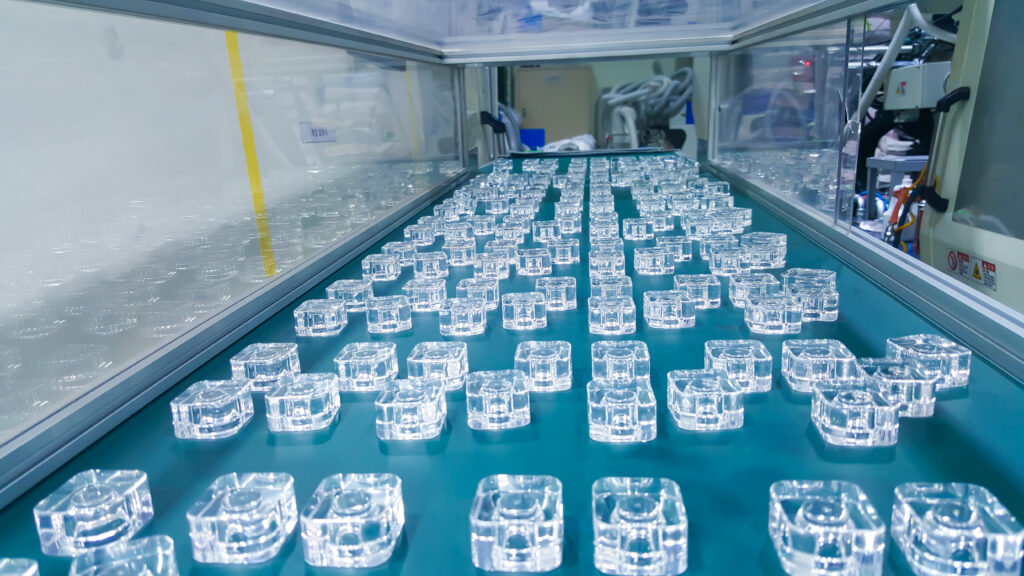

Injection molding is extensively used in the medical industry to produce components such as surgical instruments, implants, diagnostic equipment, and disposable medical items like syringes and test tubes. This process is favored for its ability to produce large volumes of parts with consistent quality, complex geometries, and tight tolerances, which are essential in medical applications.

Advantages of Using a Contract Injection Molder for Medical Components

- Expertise in Complex Designs

Contract injection molders possess specialized knowledge in creating complex and intricate designs that meet the exacting requirements of medical components.

- High-Quality Production Standards

They operate under rigorous quality control standards to ensure that every component meets the necessary medical-grade specifications.

- Cost-Effectiveness

Contract molders can offer cost-effective solutions, especially for high-volume production, reducing overall manufacturing costs without compromising quality.

- Material Selection Guidance

They provide valuable guidance on material selection, ensuring that the chosen plastics meet the functional and regulatory requirements of medical applications.

- Scalability

Contract molders can scale production up or down based on demand, offering flexibility and efficiency in supply chain management.

Benefits of Plastics in Medical Components

- Versatility

Plastics can be engineered to exhibit a range of properties, such as strength, flexibility, and resistance to chemicals and heat, making them suitable for various medical applications.

- Sterilizability

Many medical-grade plastics can be sterilized using methods like autoclaving, radiation, or chemical disinfectants, which is crucial for patient safety.

- Lightweight and Durable

Plastics are lighter than metals, reducing the weight of medical devices, and are also durable, ensuring longevity and reliability.

- Cost-Effective

Compared to other materials, plastics offer a cost-effective option for producing high-quality medical components.

Adherence to ISO and FDA Standards

The plastics industry, particularly in the realm of medical component manufacturing, strictly adheres to ISO (International Organization for Standardization) and FDA (U.S. Food and Drug Administration) standards.

- ISO 13485 Certification

This standard pertains specifically to the quality management systems in the design and manufacture of medical devices, ensuring a consistent design, development, production, and delivery of medical devices that are safe for their intended purpose.

- FDA Regulations

The FDA sets stringent regulations for medical devices, including the materials used in their construction. Injection molders must comply with these regulations to ensure that the components are safe for medical use.

- Clean Room Manufacturing

Many injection molders operate clean room facilities, which are essential for the production of medical components, ensuring that the parts are free from contaminants.

Conclusion

Injection molding plays a vital role in the medical industry, offering a reliable, efficient, and cost-effective method for producing high-quality medical components. The expertise of contract injection molders, combined with the inherent benefits of medical-grade plastics and strict adherence to ISO and FDA standards, makes injection molding an indispensable part of medical device manufacturing. As the medical industry continues to evolve, the role of injection molding in the development of innovative and life-saving devices is set to grow even further.-

This blog post is crafted to provide insights into the significant role of injection molding in the medical industry, highlighting the advantages of contract molding, the suitability of plastics for medical applications, and the industry’s commitment to regulatory standards. It aims to inform and educate readers in the medical and manufacturing sectors about the benefits and considerations of using injection molding for medical components.

Click here to speak with one of our technical sales representatives about getting started on your next project.