In this post we’ll walk through several of the benefits that come with opting for custom injection molding in the USA. As a proud American injection molding company, Montrose Molders believes in delivering excellence while supporting our local economy. Here’s why you should consider Made-in-USA for your injection molding needs:

Unparalleled Quality Standards

1. High-Quality Manufacturing

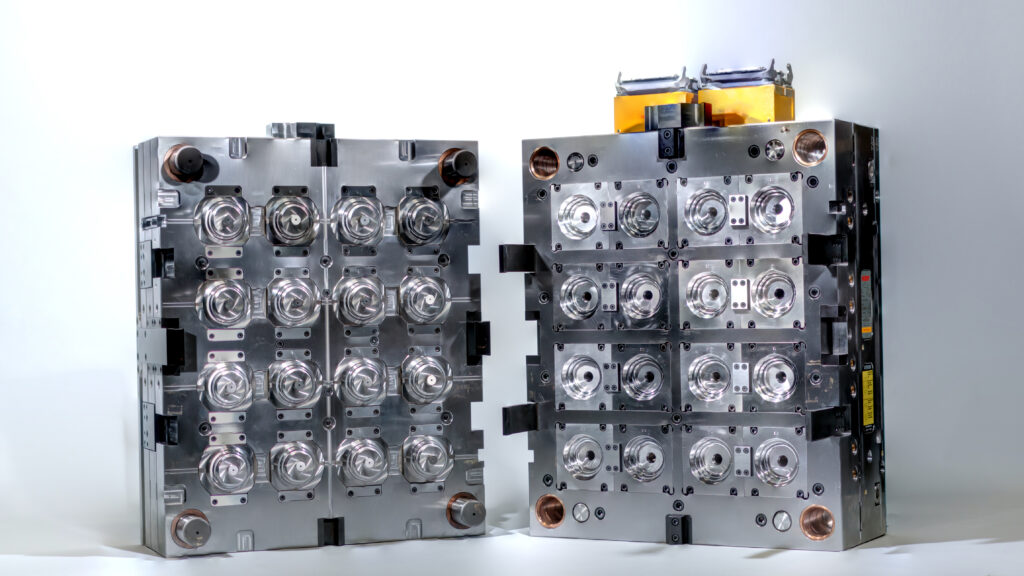

Contract injection molders based in the USA adhere to some of the highest manufacturing standards globally. This commitment to quality ensures that your products are reliable, durable, and meet stringent quality controls. Specifically, Montrose Molders operates with equipment of the latest technology and is ISO 9001 certified.

2. Advanced Technology

USA-based molders often utilize cutting-edge technology and machinery, resulting in superior precision and efficiency in production. Montrose runs on IQMS ERP, is a Soldiwords organization, and monitors all of its state-of-the-art injection molding machines with central monitoring technology to ensure that we are always running at optimal capacity.

Speed and Efficiency

3. Faster Turnaround Times

With domestic production, you benefit from significantly reduced shipping times compared to overseas manufacturing. This quicker turnaround can be crucial in fast-paced markets or when dealing with tight deadlines. In a time when port-to-port ocean shipping is more costly and time consuming, domestic contract injection molding cuts down on both inventory and lead times.

4. Streamlined Communication

Working within the same time zones facilitates smoother, more effective communication. Direct interaction with your molder can lead to more accurate and timely responses, enhancing the overall efficiency of your project.

Economic and Environmental Benefits

5. Supporting Local Economy

Choosing American injection molding contributes to the local economy, supporting jobs and communities within the USA.

6. Reduced Carbon Footprint

Domestic manufacturing often means shorter supply chains, leading to a lower carbon footprint compared to products shipped from overseas. This is a significant step towards more sustainable manufacturing practices. Manufacturing conducted in the United States is powered by cleaner energy sources than manufacturing based in Asia.

Additionally, sustainable and bio plastic options are more widely available among custom injection molding companies based in the USA.

Compliance and Safety

7. Regulatory Compliance

American manufacturers are well-versed in local and international regulations, ensuring that your products comply with relevant safety and environmental standards.

8. Intellectual Property Protection

The United States has robust laws and regulations in place to protect intellectual property rights, offering greater security for your designs and products.

Customization and Flexibility

9. Custom Solutions

Custom injection molding companies based in the USA are typically more flexible in accommodating custom requirements, whether it’s small batch production, specialized materials, or intricate designs.

10. Problem Solving and Innovation

American manufacturers are known for their problem-solving skills and innovative approaches, often leading to better solutions and improvements in product design and functionality.

—

For Injection Molding in the USA, Montrose Molders is your trusted partner.

At Montrose Molders, we are committed to providing top-tier custom injection molding services right here from the USA. Our state-of-the-art facilities, skilled workforce, and dedication to excellence ensure that your project is not just a product, but a testament to quality and innovation. Contact us today to discuss how we can bring your ideas to life, the American way..

Reach out to a technical representative today to learn more.