Understanding Standard Molds, Over-Molds, Insert-Molds, MUD Molds, and Stack Molds

When exploring custom injection molding, it’s essential to understand the variety of molds available to plastic injection molders. The type of mold used can greatly influence the efficiency, cost, and quality of the final product. In this blog, we’ll walk through the major mold types used by custom injection molders and how each serves different manufacturing needs.

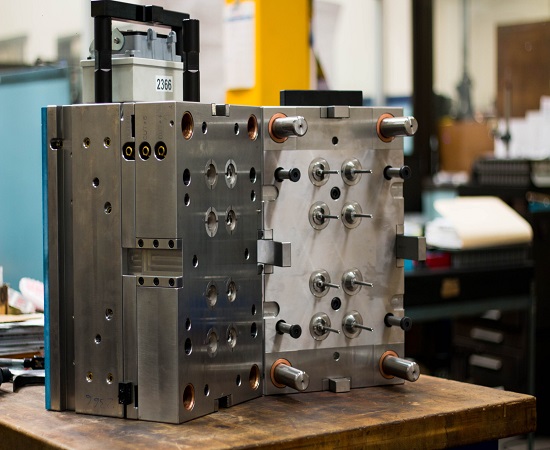

Standard Molds

Standard molds are the most commonly used in plastic injection molding. They consist of two halves—a cavity and a core—that come together to form the desired shape when molten plastic is injected. These molds are ideal for high-volume production runs of a single part and offer reliable performance for many applications.

Over-Molds

Over-molding is a process where one material is molded over another. Over-molds are used to create parts with multiple materials or colors, such as a soft grip on a hard plastic handle. This technique allows custom injection molders to enhance product functionality or appearance by combining different plastics in a single component.

Insert-Molds

Insert-molding involves placing an insert—often metal—into the mold before injecting plastic around it. This method is perfect for creating parts that require embedded components, like threaded fasteners or electrical contacts. Plastic injection molders use insert-molds to increase part strength and integrate features that would be difficult to add post-molding.

MUD Molds (Master Unit Die)

MUD molds, or Master Unit Die molds, are designed to reduce tooling costs and speed up the production process. They use a standardized base into which interchangeable inserts are placed to create different part designs. This flexibility makes MUD molds a favorite among custom injection molders who need to quickly switch between projects or produce small batch runs cost-effectively.

Stack Molds

Stack molds feature multiple mold levels, or “stacks,” which allow the simultaneous molding of two or more parts in one machine cycle. This design increases productivity without requiring additional equipment. Custom injection molders often select stack molds for applications demanding high output and efficiency, such as packaging or consumer goods.

Whether you’re working with standard molds, over-molds, insert-molds, MUD molds, or stack molds, partnering with an experienced custom injection molder ensures you get the right solution for your product’s needs. Understanding these mold types will help you make informed decisions and achieve the best results in your plastic manufacturing projects.