What is Custom Injection Molding?

At Montrose Molders, we believe in demystifying the manufacturing process to help our clients make informed decisions. One process we specialize in is injection molding—an advanced manufacturing technique that revolutionizes the production of plastic components.

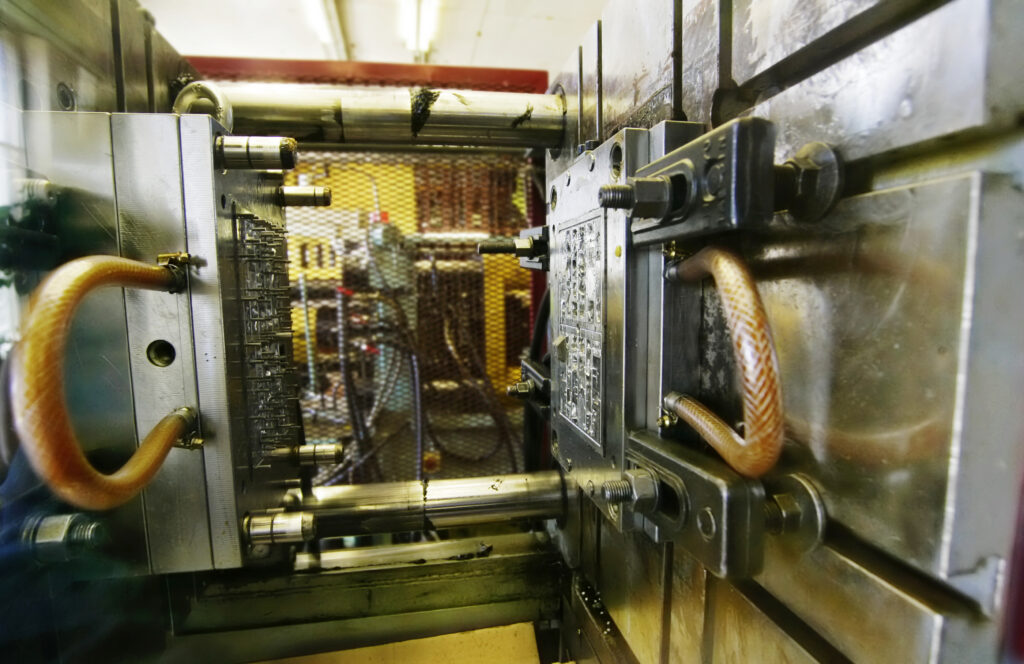

Understanding Injection Molding

Injection molding is a manufacturing process used to produce a wide range of plastic parts and products. The process involves injecting molten plastic material into a mold cavity, allowing it to cool and solidify, ultimately forming the desired shape. This method is not only fast but also yields precise and complex geometries, making it ideal for the mass production of components with high precision and repeatability.

Commonly Used Materials in Injection Molding

Below is a list of several of the most commonly used materials in injection molding. This list is not exhaustive.

- Polyethylene (PE): Known for its versatility, PE is used in a wide range of applications due to its durability and chemical resistance.

- Polypropylene (PP): PP is a lightweight and flexible material often used in packaging, automotive components, and consumer products.

- Acrylonitrile Butadiene Styrene (ABS): Recognized for its impact resistance and strength, ABS is popular in the production of consumer goods and automotive parts.

- Polycarbonate (PC): PC offers exceptional optical clarity and high impact resistance, making it suitable for applications such as electronic components and medical devices.

- Polyethylene Terephthalate (PET): PET is commonly used in the production of bottles and packaging materials due to its transparency and recyclability.

- Nylon (PA): Known for its strength and resistance to abrasion, nylon is often used in applications requiring high durability, such as gears and bearings.

Why Choose Montrose Molders for Your Custom Injection Molding Project

Choosing the right partner for your injection molding project is crucial, and Montrose Molders sets itself apart with a commitment to excellence and client satisfaction. Here’s why you should trust us with your custom injection molding needs:

- Expertise: With years of experience, our team possesses the expertise needed to tackle complex projects and deliver high-quality results.

- State-of-the-Art Facilities: Montrose Molders invests in cutting-edge technology and equipment to ensure precision, efficiency, and consistency in every project.

- Customization: We understand that every project is unique. Our ability to customize solutions, from material selection to design intricacies, ensures that your specific requirements are met.

- Quality Assurance Our stringent quality control measures guarantee that each product meets the highest standards before it reaches your hands. Montrose is ISO 9001 certified and is pursuing an ISO 13485 certification.

- Collaborative Approach We believe in open communication and collaboration throughout the project, ensuring that your vision is realized at every step of the injection molding process.

At Montrose Molders, we’re not just a custom injection molder; we’re a reliable ally committed to bringing your ideas to life. Contact us today to discuss how our contract injection molding expertise can contribute to the success of your project.